A benchmark for performance and reliability

WindFloat Atlantic was the first full-scale floating wind farm to use semi-submersible technology and the first floating wind project to secure bank financing.

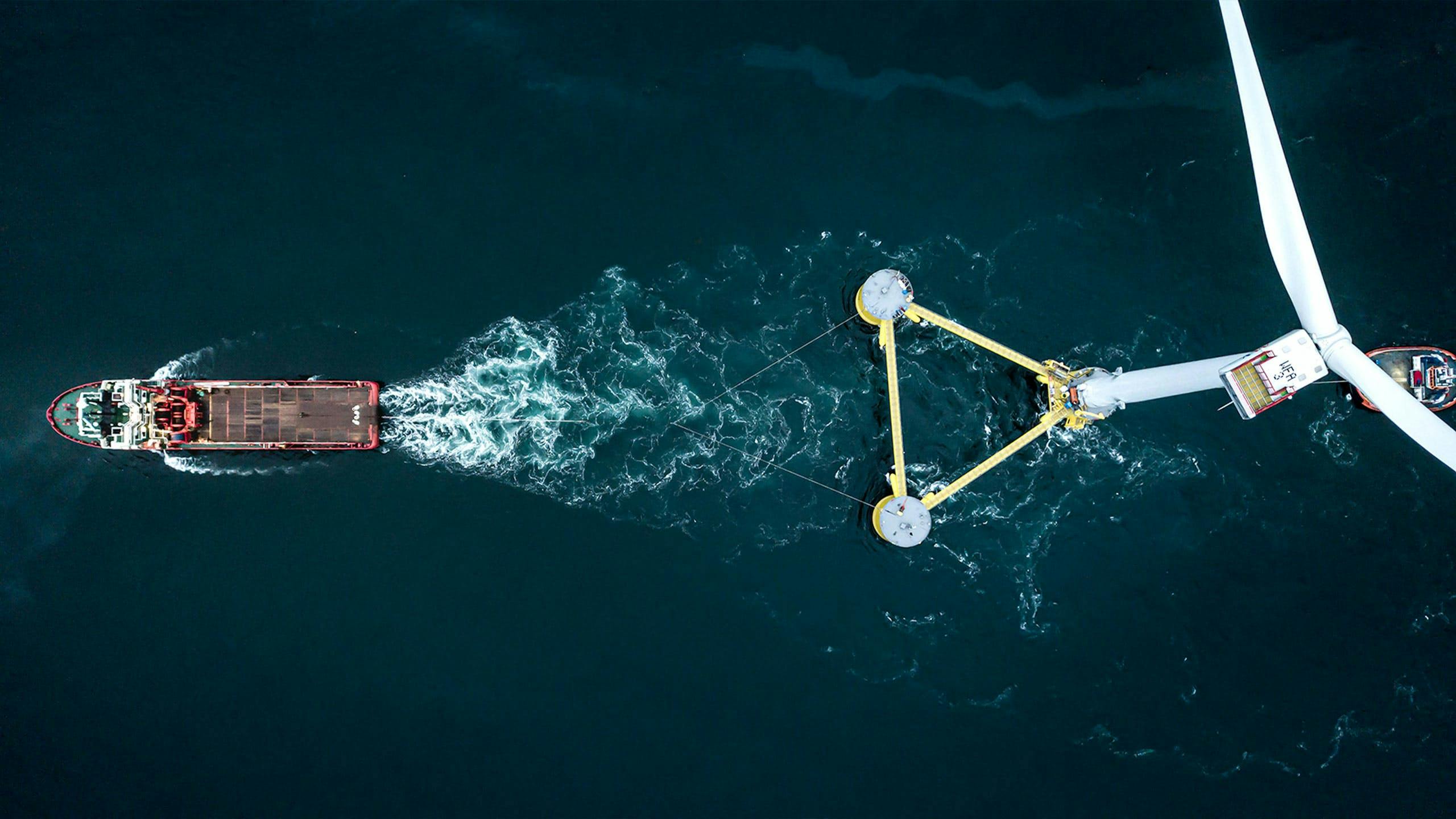

Operating 20 km offshore Viana do Castelo, in Portugal, the project features 3 WindFloat T units, which host 8.4 MW Vestas V164 wind turbines. The three giant turbines stand tall at 185 m above the ocean surface, and the three WindFloat® platforms are anchored to the seabed 100 m below with a catenary mooring system.

Principle Power designed the platforms through a direct contract with WindPlus, a majority owned subsidiary of Ocean Winds, and supported execution by providing Technical Execution Advisory Management (TEAM) services throughout fabrication, offshore construction, and commissioning. Principle Power continues to provide platform Operations & Maintenance (O&M) services to WindFloat Atlantic.

The close relationship between all project stakeholders allowed Principle Power to complete testing our execution-phase processes and methods, while bringing field data to further refine the engineering models that we use to optimizing the design of WindFloat® technologies for upcoming projects.

First power

2020

Project capacity

25 MW

Wind turbine

Vestas V164

Wind turbine capacity

8.4 MW

Design life

25 years

Distance to shore

20 km

Water depth

100 m

Homes and businesses powered

25,000 (annually)

Project sponsors

Ocean Winds, Tokyo Gas, Repsol

Financing

European Investment Bank, €60 million loan

Certification

American Bureau of Shipping, DNVGL

The value of experience

The WindFloat Atlantic project was built on the foundation of the WindFloat 1 project, which generated power for five years in extreme Atlantic Ocean conditions at a site just 50 km to the south.

This proven track record provided the WindPlus consortium, banks, and suppliers the confidence to take the next step in floating technology: a project with a 25-year business case, featuring the largest commercially available wind turbines, and a host of other technologies, including, among others, 66 kV inter-array cables and disconnectable mooring and cabling systems to enable future commercial scale floating wind projects.

WindFloat Atlantic has been operating since 2020, delivering a cumulative 320 GWh of energy over its four years of operation (above initial expectations). The project also shown resilience in extreme weather conditions, like Ciaran Storm, when the WindFloat® units withstood 20-meter waves and wind gusts of 139 km/h without any structural damage.

WindFloat Atlantic is generating valuable empirical data that we use to refine our models and processes, further optimizing the next generations of WindFloat® technology. These operational insights are a vital input for the design process and construction methods, enabling cost and risk reduction, as well as optimized manufacturing processes for industrial-scale deployment.

Related news

The WindFloat® advantage

PerformanceFabricationInstallationInspection, Maintenance & RepairConnectionLocal CommunitiesEnvironmentServices

Project Development SupportConcept and Pre-FEED DesignFEED and Detailed DesignProject Execution SupportInspect, Maintain & RepairEnd of Life Services