Environment

The WindFloat® product portfolio is designed to have minimum environmental impact throughout its lifecycle.

Our commitment to the environment

At Principle Power, we endeavor to make a positive impact on the planet and its people. We are continuously looking at ways to minimize our environmental footprint and that of our industry.

We support our customers to reach their environmental ambitions. We do this by providing sustainable solutions and services to deploy floating offshore wind at scale and with minimal environmental impact through safeguarding biodiversity and promoting the sustainable use of our oceans.

Our commitment to our oceans

Principle Power has a voluntary commitment to support the implementation of Sustainable Development Goal 14, widely known as SDG 14, which aims to conserve and sustainably use the oceans, seas, and marine resources.

Developing the Ocean Economy and unleashing untapped business opportunities are key components of tackling these issues. The offshore wind sector is a major growth industry in the ocean space, with floating wind, in particular, being a major driving force in its globalization and expansion.

We believe that the sector can, and should, play a key role in actively contributing to the realization of the SDG 14 goals. Working with others, including the World Ocean Council, Principle Power commits to establishing a framework for discussion on issues associated with the floating offshore wind and commercial fishing industries, identifying strategies and approaches to optimize the sustainable development and economic opportunity potential for both. We recognize that each plays an important existing and future role in coastal economics and policy.

Responsible siting beyond the horizon

Floating offshore wind has a lower environmental impact when compared with conventional fixed‐bottom offshore wind: in most cases, there is no pilling or drilling during the noise-free installation process.

The WindFloat® technology relies on standard, proven, and minimally invasive offshore mooring methodologies that mitigate environmental and ecological impact to the seabed. The WindFloat® product portfolio can be sited irrespective of depth and seabed conditions, which provides an increased ability to choose sites with the least environmental impact and conflict with other ocean users.

Protecting nature and biodiversity

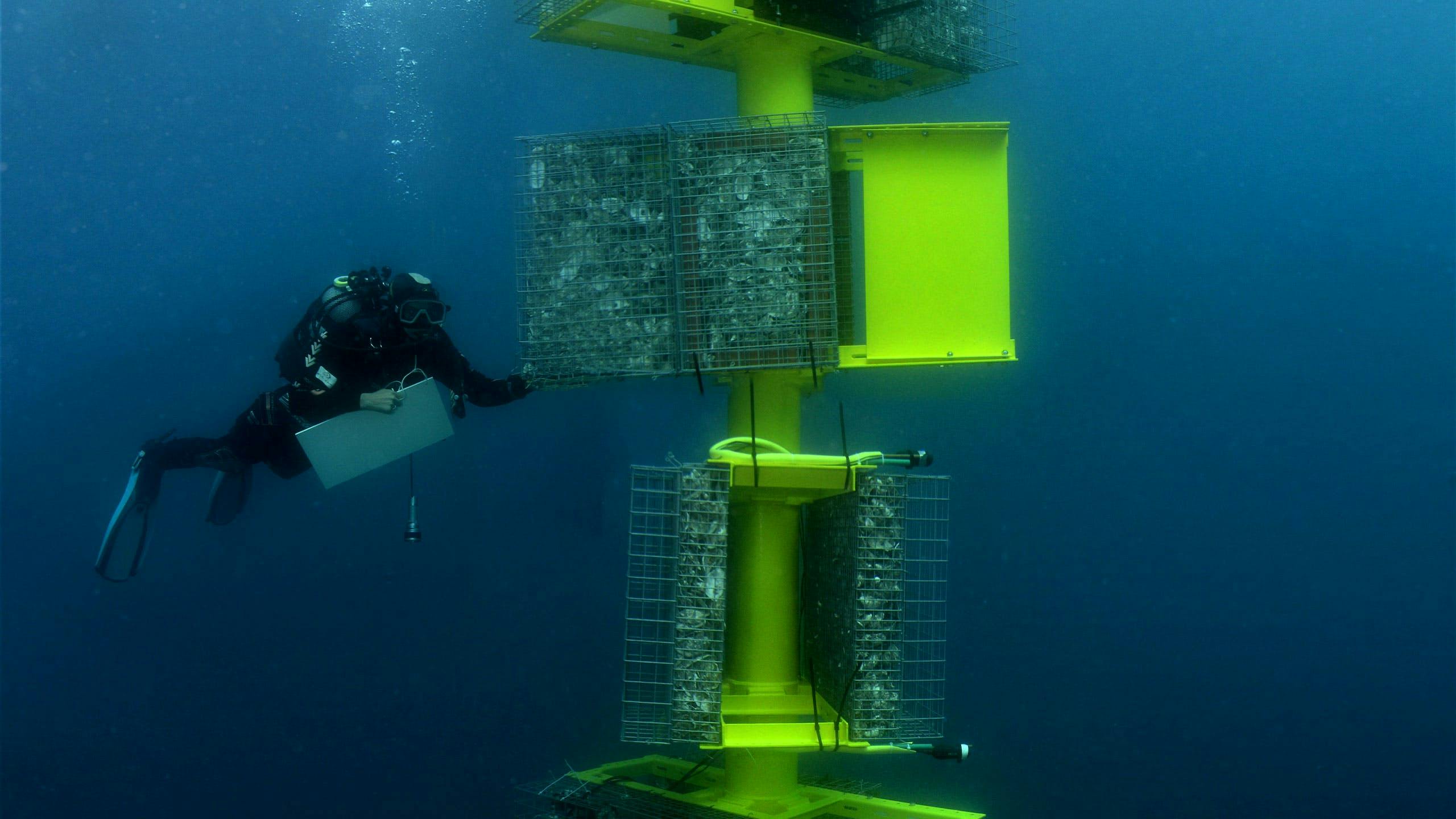

Floating offshore wind farms can support marine wildlife by creating additional habitats and attracting new species. The WindFloat® product portfolio - either the WindFloat T and WindFloat F - can act as an artificial reef and provides shelter and refuge habitat for a variety of species during the operations phase.

We are working with our clients to explore the potential to leverage this "artificial reef effect" on various projects to increase local biodiversity.

Photo © Remy Dubas/Ecocean

Photo © Remy Dubas/Ecocean

Our EFGL project in France features Biohuts® or artificial fish habitats that have shown to be effective at fostering increased marine life activity, accommodating for any displacement of fishing activities within a floating offshore wind farm.

With this project, we are building our knowledge of how the WindFloat® product portfolio - either the WindFloat T and WindFloat F - can support marine life within our projects.

Our commitment to decarbonizing the value chain and to sustainable use of resources

We strive to contribute to a transition to a circular economy, optimizing the use of resources such as energy, fuel, and raw materials.

Our vision is a truly circular economy where the WindFloat® units are fabricated with steel produced from "green" hydrogen using 100% renewable energy.

The WindFloat® allows for onshore assembly and turbine installation, reducing overall cost and risk to the environment. Performing all heavy lifts and pre-commissioning the system onshore in a protected environment dramatically reduces offshore activities, forgoing expensive and carbon-intense vessels. Tow-out and installation can be performed with simple tugboats which have the potential to transition to low carbon fuels.

On inspection, maintenance & repair, the use of robotics and digital twins to monitor an offshore wind array reduces the number of trips offshore and thereby minimizes the vessels' requirements.

Decommissioning and recyclability

Principle Power offers Life Extension studies to assess the potential of WindFloat® units' ability to continue operating beyond its initial design life, further extending its usefulness in producing clean, renewable energy.

When the time comes, WindFloat® units can be decommissioned using simple procedures with minimal environmental impact.

Each platform is disconnected from the array and towed back to quay for dismantling. Anchors and mooring legs can also be recovered, with minimal disturbance to the seabed. Because WindFloat®’s are fabricated from steel, the material can be recycled and turned into a new WindFloat®.

We have demonstrated the ease of our decommissioning process already at the WindFloat 1 demonstration project in Portugal.

The WindFloat® advantage

PerformanceFabricationInstallationInspection, Maintenance & RepairConnectionLocal CommunitiesEnvironmentServices

Project Development SupportConcept and Pre-FEED DesignFEED and Detailed DesignProject Execution SupportInspect, Maintain & RepairEnd of Life Services