Offshore wind turbines are connected to the onshore electrical grid by a network of subsea power cables. Inter-array cables link the individual units in an offshore wind farm, gathering power for export to the shore via an export cable. While small projects can be connected directly to shore at the inter-array cable voltage, larger projects typically include one, or more, offshore substations to step the power up to high voltage for increased efficiency.

The I-tube connector

The I-tube, coupled with the WindFloat® plug-n-play approach to mooring connection, revolutionizes maintenance for offshore wind turbines, enabling tow-to-shore strategies for large correctives.

Principle Power designed the I-tube, a patented plug-n-play connector, to allow for the simple connection and disconnection of a WindFloat® unit from the inter-array cable network. Once deployed, the I-tube acts as a spar, floating on the surface and maintaining electrical connection between the wind turbines. This system allows power to flow uninterrupted throughout the array if any given unit is removed for a wind turbine large corrective.

These systems allow all heavy lifting to be performed in the sheltered port environment, removing the need for extremely expensive vessels that would otherwise be required to perform risky floating-to-floating lifts in the exposed offshore environment

Dynamic inter-array cables

A key difference from fixed-bottom wind farms is that inter-array cables in a floating wind farm are suspended between platforms and the seabed. As a result, these cables must be dynamic to withstand expected motions within the water column, as constrained by the mooring system. Due to dependencies between these systems, Principle Power adopts an integrated approach to the design of the WindFloat®, cable architecture, and mooring system design to deliver an optimized solution.

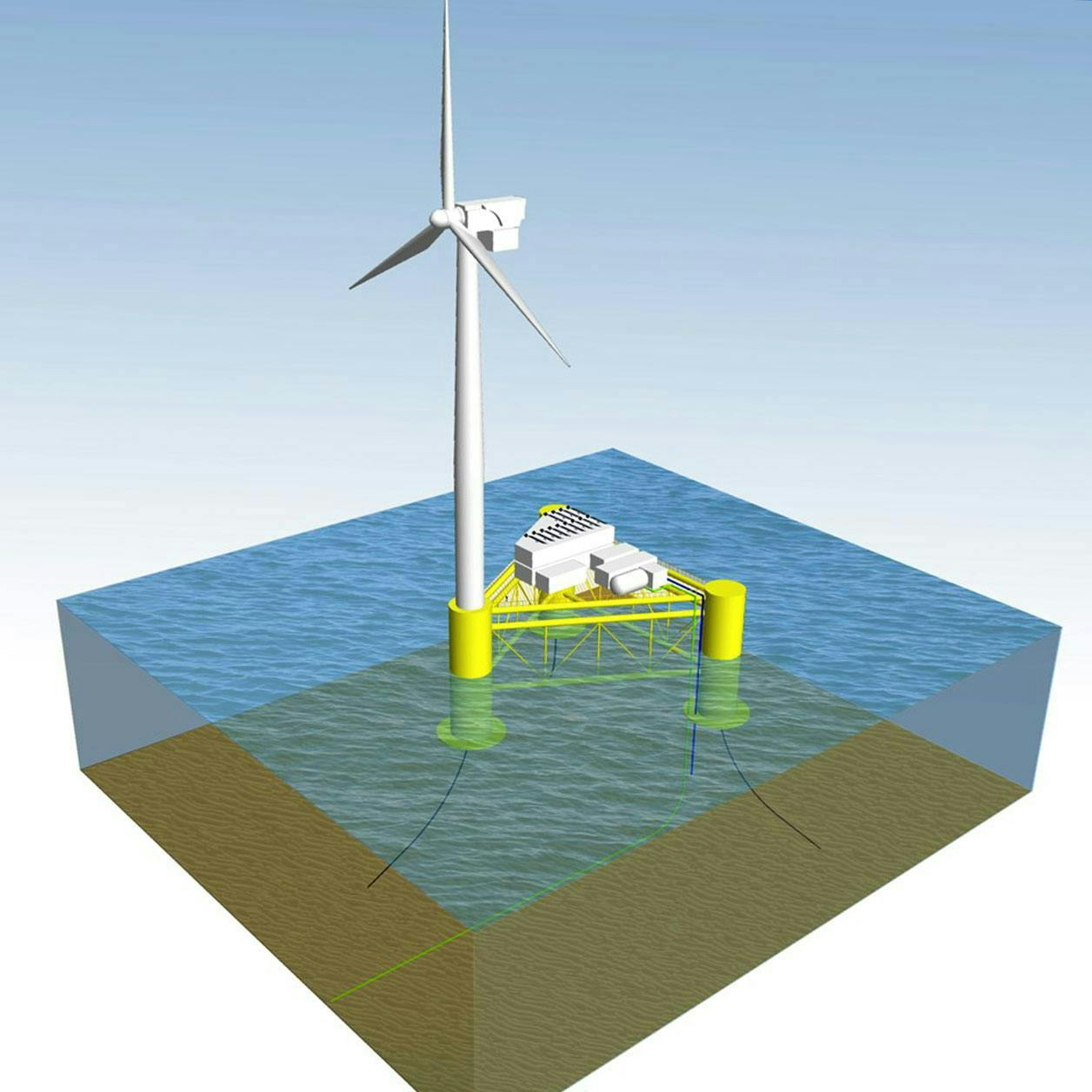

Floating substation export system

Smaller projects (typically below 100 MW) can be connected directly to shore at the inter-array cable voltage with an export cable running from the last unit on the string to the point of cable landfall. Larger projects typically require an offshore substation to step up power from the collection voltage of the inter-array cable system to the export voltage (typically 132 kV to 220 kV).

Depending on the water depth, the substation can either be located on a fixed foundation or a floating platform. Principle Power offers an adapted WindFloat® portfolio design suitable to support offshore substation topsides. Leveraging similar platform designs for both wind turbines and substations offers significant procurement cost efficiencies.

Illustration by ERM

Floating “green” hydrogen

Today, offshore wind farms produce electricity and are therefore dependent on proximity to population centers and a robust transmission network.

Offshore wind “green” hydrogen, which would involve the production of hydrogen from offshore wind power, could remove this locational constraint by creating a commodity fuel that can be stored and transported for use on demand.

Offshore wind "green" hydrogen could be a game-changer for the global energy sector. It would allow projects to be sited in the locations with the best wind resources. The ability to output a stable fuel, instead of electrons, would allow offshore wind to reach a broader customer base, including sectors like shipping, aviation, and heavy industry that represent the biggest decarbonization challenges.

Principle Power is a partner in the ERM Dolphyn project, a world-first project that aims to produce "green" hydrogen directly from floating wind turbines, with all desalinization and electrolysis facilities integrated onto a WindFloat® platform.

Let's get your project floating

Contact our expert team to learn about how we can support your floating wind project.

The WindFloat® advantage

PerformanceFabricationInstallationInspection, Maintenance & RepairConnectionLocal CommunitiesEnvironmentServices

Project Development SupportConcept and Pre-FEED DesignFEED and Detailed DesignProject Execution SupportInspect, Maintain & RepairEnd of Life Services