EU H2020 Atlantis

Operational expenditures account for up to 30% of the total cost of energy for offshore wind projects. The ATLANTIS project explores robotic solutions to enable safer and efficient inspection, maintenance & repair activities.

Scope

Inspection, Maintenance, and Repair

Funding

European Commission (H2020)

Total budget

€7,046,271

Kick-off

Q1 2020

Duration

48 months

Project lead

INESCTEC

Partners

Principle Power, VTT, EDP NEW, IQUA Robotics, RINA, ABB, Universitat de Girona, SpaceApplications Services, ECA Group

The Atlantic Testing Platform for Maritime Robotics

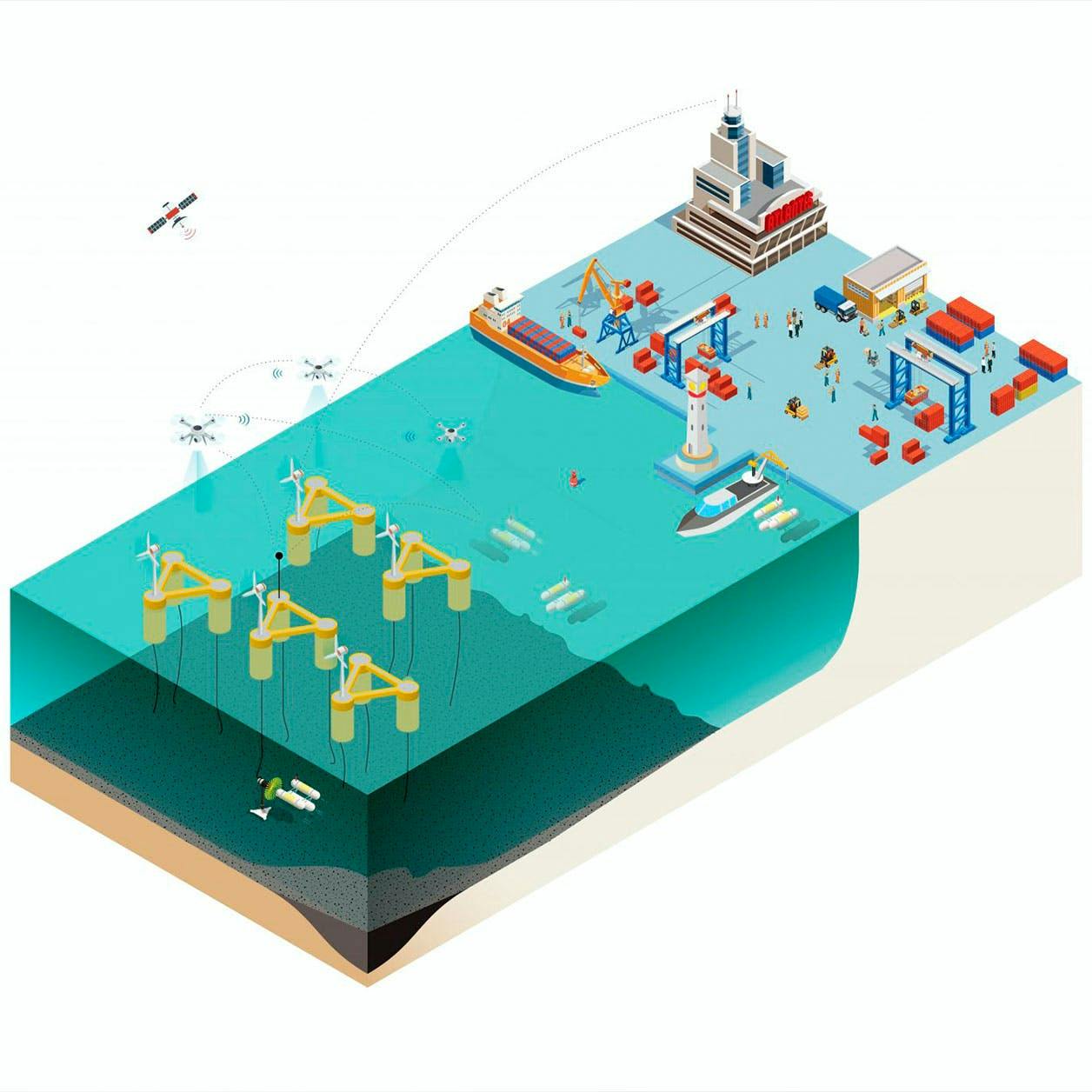

ATLANTIS promotes the use of robotics in offshore wind farms to reduce the Levelized Cost of Energy (LCOE) by eliminating, or minimizing, the use of supporting vessels for inspection and maintenance operations at offshore wind farms.

The ATLANTIS project is establishing pioneering test infrastructure in Viana do Castelo, Portugal to pilot robotic technologies with high potential for offshore wind inspection and maintenance applications. Successful concepts will then be piloted in the open ocean environment at the WindFloat Atlantic project, installed 20 km offshore, to validate performance in the real world.

The project objectives are:

- Deployment of a large-scale pilot featuring weather and sea state conditions from the Atlantic Ocean at Viana do Castelo, Portugal

- Design of new industry-oriented showcases describing concrete scenarios for the inspection and maintenance below and above water

- Operation and demonstration of the robotics solutions at WindFloat Atlantic

- Improve heterogeneous robots for inspection and maintenance activities with varying levels of automation to enable robots to reach technological maturity and commercial readiness level

- Promoting robotics in supply chains by demonstrating the beneficial role in terms of increased inspection and maintenance efficiency and reduced life-cycle costs for a real offshore wind farm

- Assessing the added value and the risk of inspection and maintenance activities performed by robots

- Develop guidelines towards a new standardization and certification around robotic-based inspection and maintenance activities in offshore wind

Principle Power is proud to have partnered with this consortium of industry and academic experts to support the development of robotic solutions that may be true game-changers for the future of offshore wind Inspection, Maintenance, and Repair operations.

- Clara Moura Santos, Strategy and Commercial Manager at Principle Power

The WindFloat® advantage

PerformanceFabricationInstallationInspection, Maintenance & RepairConnectionLocal CommunitiesEnvironmentServices

Project Development SupportConcept and Pre-FEED DesignFEED and Detailed DesignProject Execution SupportInspect, Maintain & RepairEnd of Life Services