ERM Dolphyn

Developing an integrated floating wind and “green” hydrogen production facility.

Scope

Wind-to-Hydrogen

Funding

Department for Business, Energy & Industrial Strategy (UK)

Total budget

£3,120,000

Kick-off

Q4 2020

Duration

10 MW by 2026

Project lead

ERM (Environmental Resources Management)

Partners

Tractebel, ODE (Offshore Design and Engineering), Principle Power, NEL, Doosan

Floating wind to “green” hydrogen

With global energy demand increasing, and an urgent need to decarbonize the current energy mix, hydrogen has emerged as an alternative to fossil fuels and catapulted to the forefront of the net-zero toolbox. To truly deliver on its environmental potential, hydrogen needs to be produced from our planet’s vast renewable energy resources.

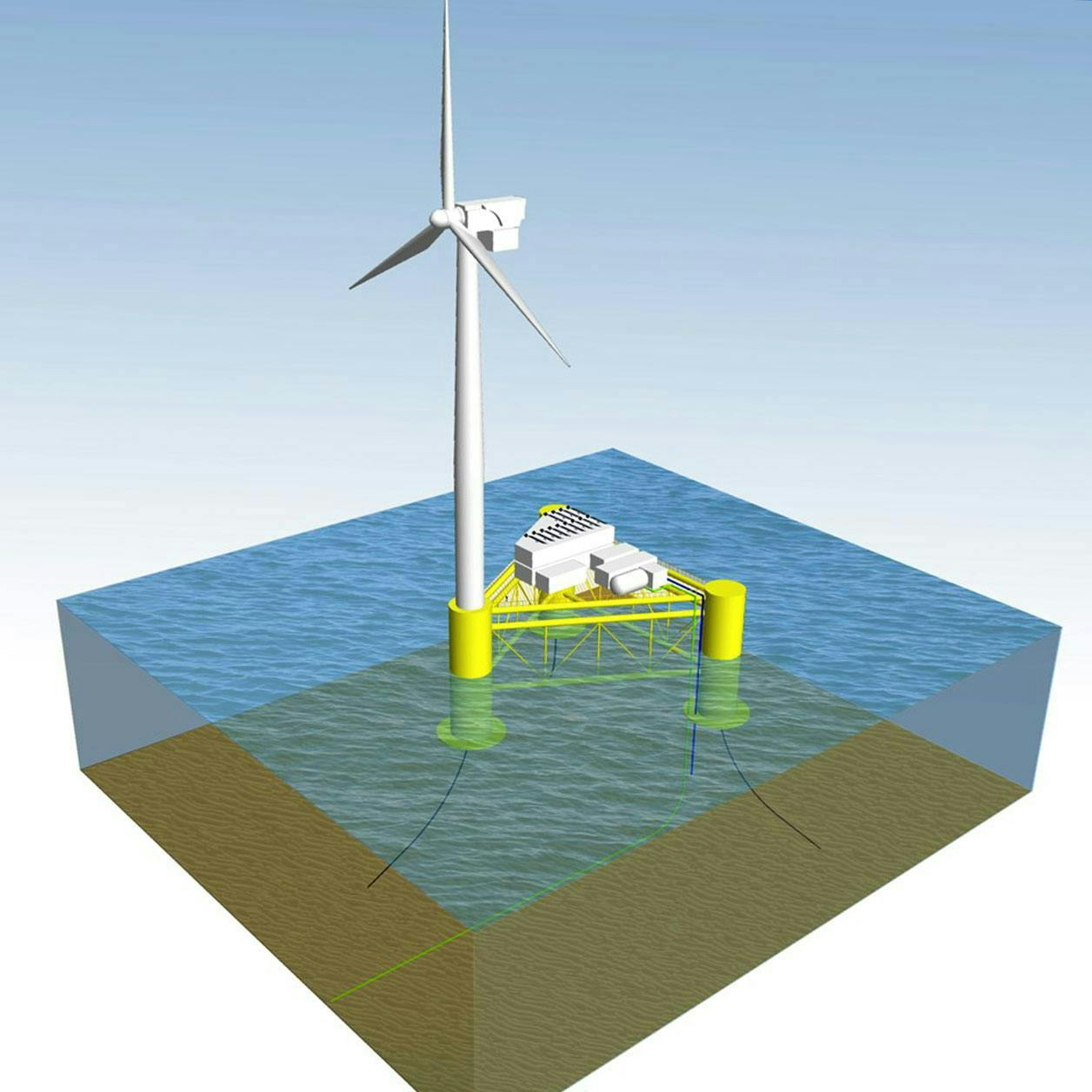

The ERM Dolphyn (Deepwater Offshore Local Production of HYdrogeN) aims to deploy a 10MW wind turbine integrated polymer electrolyte membrane electrolyzer on a WindFloat® platform.

This will enable the export of "green" hydrogen to shore from deep water sites via a subsea pipeline.

Illustration by ERM

The design is currently at FEED (Front End Engineering Design) stage and consists of a large-scale floating wind turbine with an integrated water treatment unit and proton exchange membrane (PEM) electrolyser for localised hydrogen production. It incorporates its own standby power unit, supplied by hydrogen stored on the facility, and is therefore completely autonomous, requiring no electrical connection to shore.

The concept is being developed and led by ERM with support from industry frontrunners, including Tractebel Engie and Principle Power. Principle Power’s WindFloat® platform will be equipped with a V80 10 MW wind turbine and a platform deck supporting the hydrogen production factory. This prototype, expected to be deployed in 2026, will be installed in the UK. The resulting hydrogen will then be exported to shore under pressure via a flexible riser.

The Dolphyn concept allows the wind turbines to operate completely independent of the grid, removing the need for complex and costly electrical equipment. When deployed at industrial scale, this innovative technology, coupling floating wind with hydrogen production, offers the potential to deliver the immense volumes of hydrogen that will be required to decarbonize everything, from electricity to transportation to heavy industry. The technology has the potential to enable the truly circular offshore wind farm of the future, where new wind turbines and platforms are fabricated from zero-carbon steel produced using green hydrogen.

ERM estimates that a single 10 MW turbine can produce more than 900 t of hydrogen per year. A full-scale commercial wind farm composed of 400 units, with an installed capacity of 4 GW, could produce over 320,000 t of hydrogen per year, enough to heat more than 1.5 million homes.

The WindFloat® advantage

PerformanceFabricationInstallationInspection, Maintenance & RepairConnectionLocal CommunitiesEnvironmentServices

Project Development SupportConcept and Pre-FEED DesignFEED and Detailed DesignProject Execution SupportInspect, Maintain & RepairEnd of Life Services