Principle Power is a proud sponsor of GWEC’s 16th flagship Global Wind Report 21

Is green hydrogen the perfect match for floating offshore wind?

As a proud Associate Sponsor for GWEC’s 16th flagship Global Wind Report 21, we discuss how green hydrogen can be the perfect match for floating offshore wind. With global energy demand increasing, and an urgent need to decarbonize the current energy mix, hydrogen has emerged as an alternative to fossil fuels and catapulted to the forefront of the net-zero toolbox. Hydrogen energy is extremely versatile.

The report shows that, despite a new record year for the wind power industry in 2020, growth will need to triple over the next decade to meet our planet’s climate goals. We believe floating offshore wind will be a key technology on the road to net zero.

Download the full report here or read our Wind-to-Hydrogen case study below.

Is green hydrogen the perfect match for floating offshore wind?

With global energy demand increasing, and an urgent need to decarbonize the current energy mix, hydrogen has emerged as an alternative to fossil fuels that has catapulted to the forefront of the net-zero toolbox. Hydrogen energy is extremely versatile, in that it can be stored in either gas or liquid form and can be converted into electricity or transportation fuel when needed, with water as the only by-product.

The bulk of hydrogen currently in use is derived from fossil fuel feedstock using energy-intensive and polluting processes (grey hydrogen). If hydrogen is to truly deliver on its environmental potential, it needs to be produced from our planet’s vast renewable energy resources (green hydrogen).

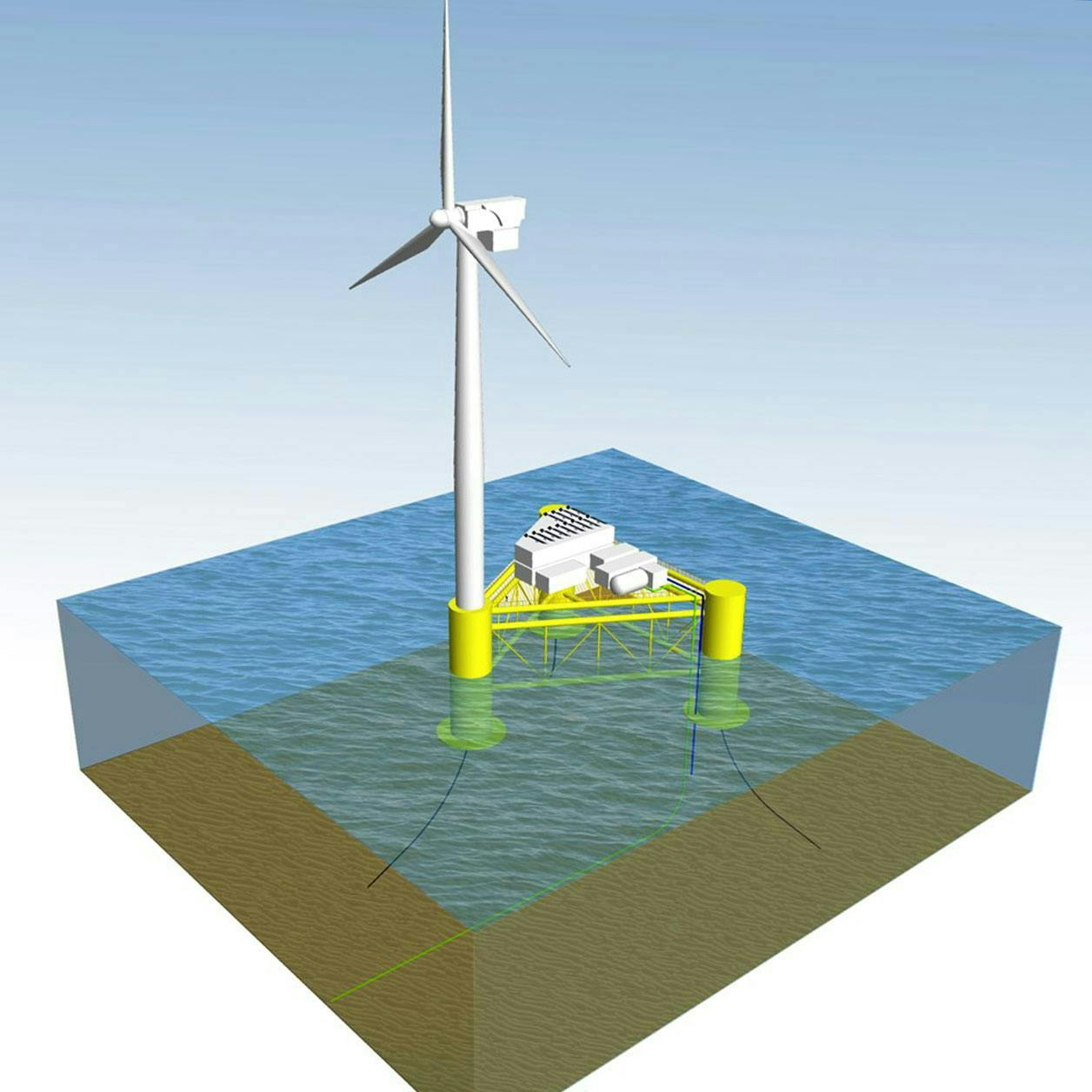

Illustration by ERM

The ERM Dolphyn project aims to produce green hydrogen from floating wind turbines situated miles out to sea, a world-first.

The design is currently at FEED (front end engineering design) stage and consists of a large-scale floating wind turbine with an integrated water treatment unit and proton exchange membrane (PEM) electrolyzer for localized hydrogen production. It incorporates its own standby power unit, supplied by hydrogen stored on the facility, and is therefore completely autonomous, requiring no electrical connection to shore. The first phase is initially aiming to get a 2MW proof of concept unit up and running by 2024.

The concept is being developed and led by ERM with support from industry frontrunners including Tractebel Engie and Principle Power, who are responsible for the floating sub-structure design and the wind turbine. Principle Power’s WindFloat® platform will be equipped with a V80 2 MW wind turbine and a platform deck supporting the hydrogen production factory. The hydrogen will then be exported to shore under pressure via a pipeline.

The Dolphyn concept allows the wind turbines to operate completely independent of the grid, removing the need for complex and costly electrical equipment, and setting the roadmap for cost competitiveness with grey hydrogen. When deployed at industrial scale, this innovative technology, coupling floating wind with hydrogen production, offers the potential to deliver the immense volumes of hydrogen that will be required to decarbonize everything, from electricity to transportation to heavy industry.

The WindFloat® advantage

PerformanceFabricationInstallationInspection, Maintenance & RepairConnectionLocal CommunitiesEnvironmentServices

Project Development SupportConcept and Pre-FEED DesignFEED and Detailed DesignProject Execution SupportInspect, Maintain & RepairEnd of Life Services